fully automatic bottle blowing moulder description:

Double servo system bottle blowing machine

Simple and stable

Fast speed

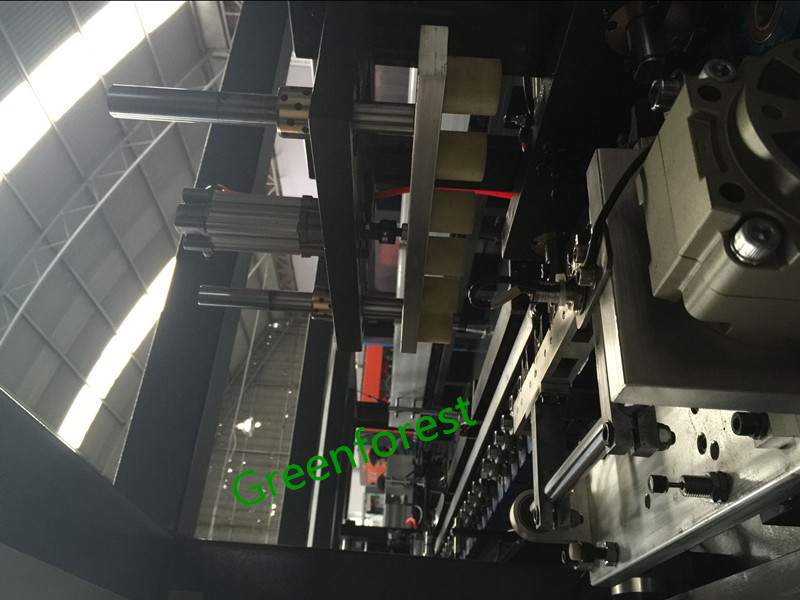

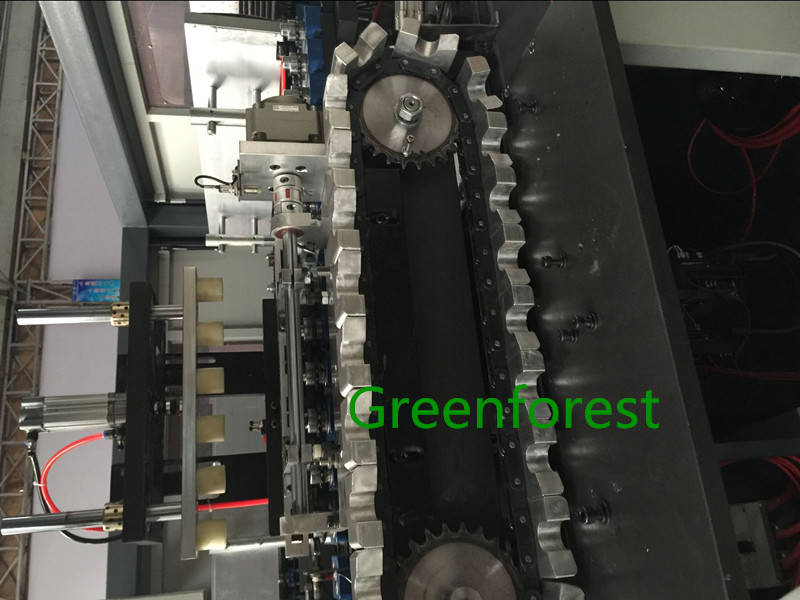

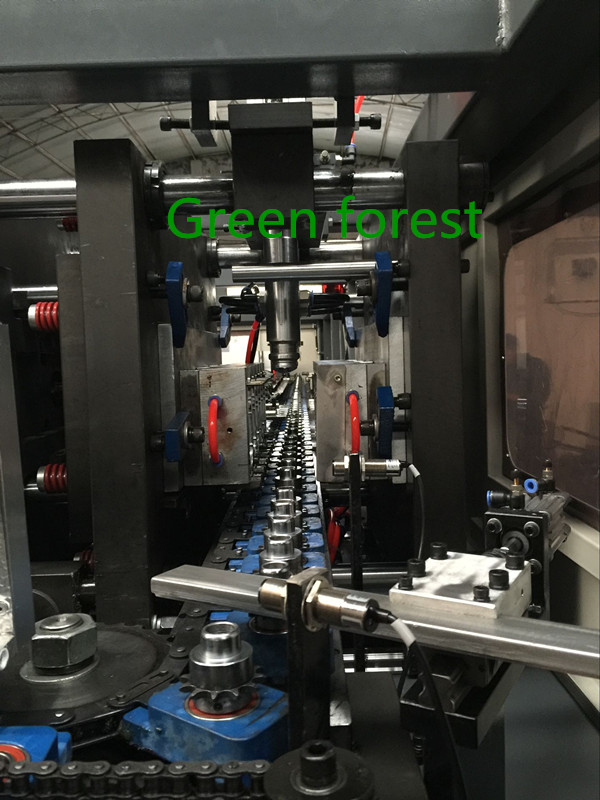

Nice inner structure

Energy saving!

Hot sale product!

Suitable to blow: 10ml-600ML PET bottle which is used in drinking water/cosmetic bottles/daily food bottles

Welcome to visit our machine !

Blowing machine feature:

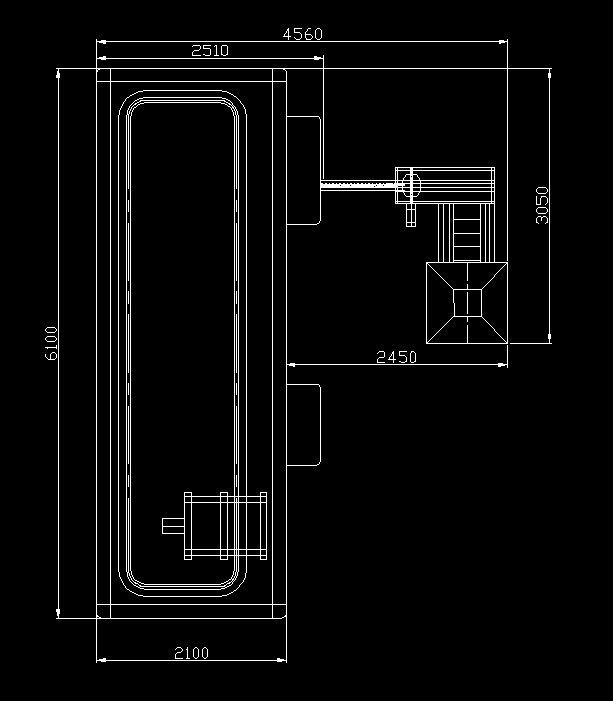

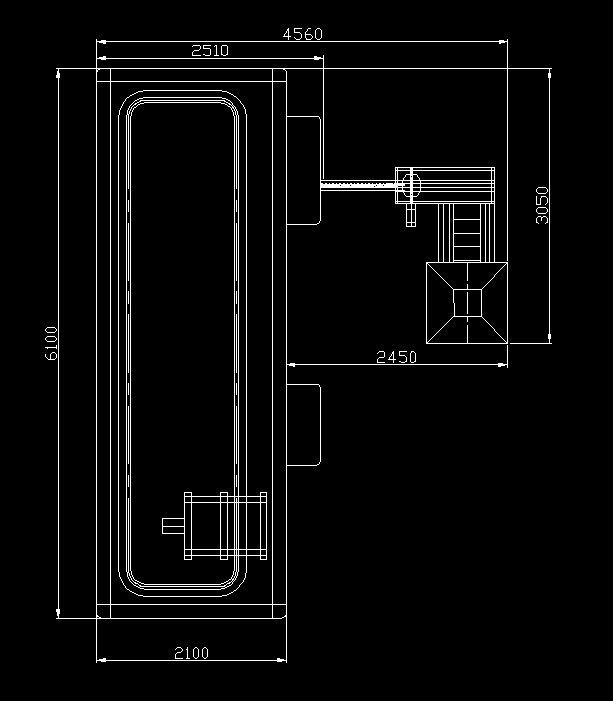

1.Compact design saves much space.

2.Adopts double servo system,keep high speed.

3.Automatic sending preform system,stably sending pet preform.

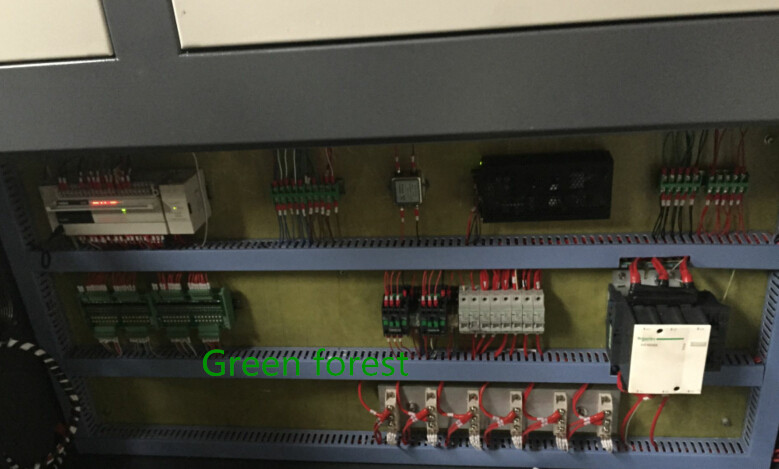

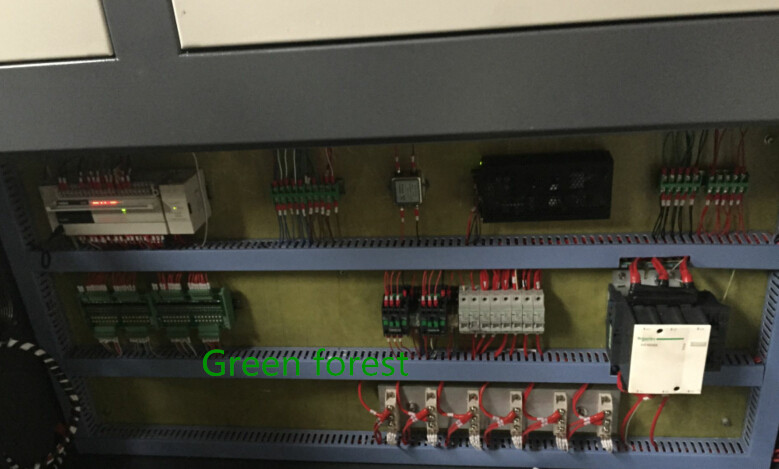

4.Controlled by PLC system,convenient and smart touch screen

5.Independent line running system,simple and stable.

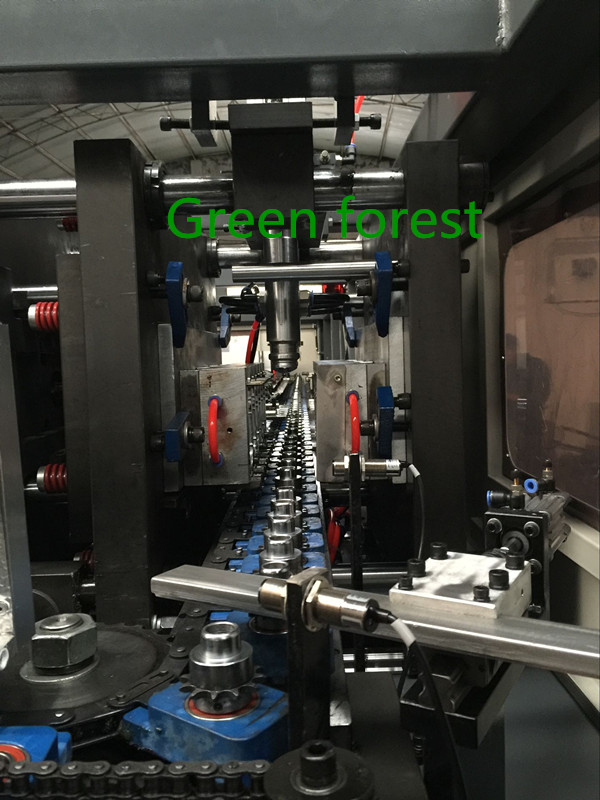

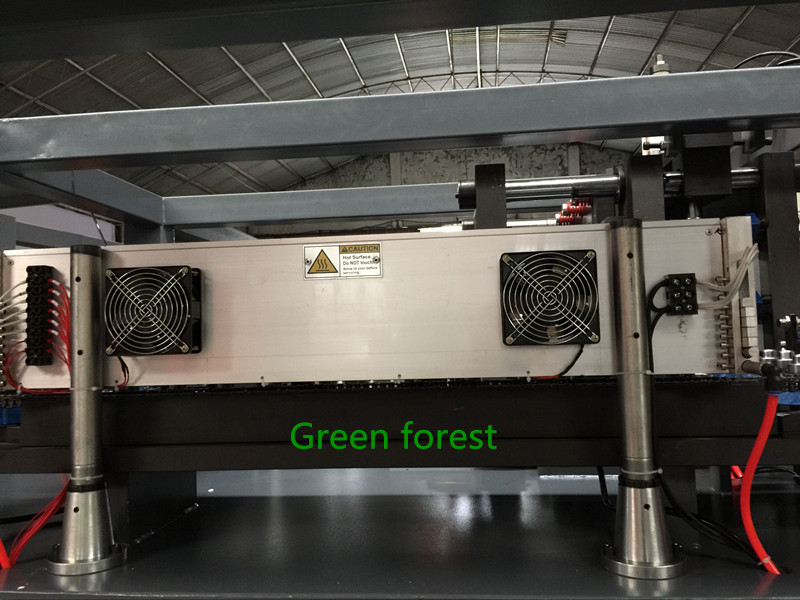

6.Special heating system,adopting infrared lamp heating system with right temperature controlling,strong penetrability, the preform rotates and is heated uniformly. Also easy to adjust.

7.Special air storage device,which have 3 separate air tanks.Each work process have one tank,for example,action/preform pre-blowing / blowing,these have 3 air tanks to satisfy the different requirement for air pressure.

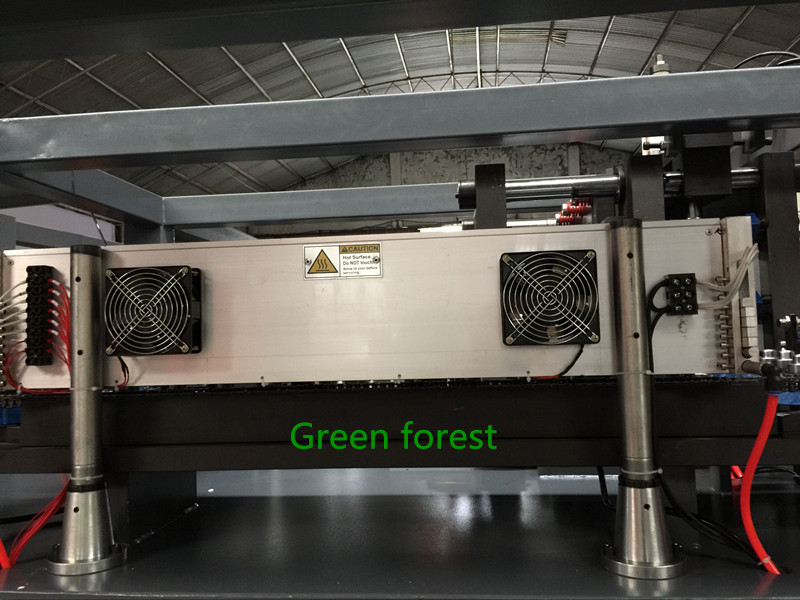

8.Cooling system effects well,which can keep the bottleneck good shape,won’t be affected by the infrared lamp.

9.Action is driven by cylinder not by oil pump,like this,the bottles won’t have oil pollution.

10.Self-lock device for security is available for every mechanical action. When any of the actions has trouble, machine program will switch to state automatically.

11.Adopting high pressure mode locking, the bottles don’t have obvious molding line.

12.The machine is fully automatic,low cost,highly effect,simple operation and easy maintenance.

13.The operation have two choices of by manual and automatic operation.Convenient for adjusting and installing.

14.Rejection rates is reduced to a minimum.

Configuration:

|

Spare parts |

Products name |

Original |

Brand |

|

Electrical |

Magnetic switch |

South korean |

Autonics |

|

PLC |

Japan |

Mitsubishi |

|

Air switch |

French |

Schneider |

|

Touch screen |

Japan |

Mitsubishi |

|

Switch power supply |

South Korean |

Black shell |

|

Switches |

French |

Schneider |

|

Relay |

Japan |

Omron |

|

AC contactor |

French |

Schneider |

|

Circuit breaker |

French |

Schneider |

|

Highpressure silencer |

America |

ALWITCO |

|

Bottle preform testing |

Japan |

Omron |

|

Solenoid valve |

Operating valve |

South korean |

PMC |

|

Air cylinder |

Japan |

SMC |

|

Mechnical |

Clamping guide |

TaiWan |

YinTai |

Products specificaton:

Products specificaton:

|

Specification |

Unit |

|

|

No. Of cavity |

Cav |

6 |

|

Cavity pitch |

mm |

76.2 |

|

Max capacity |

ml |

600 |

|

True production |

600ml(16g) |

7000BPH |

|

Heating pitch |

mm |

76.2 |

|

Preform holder |

pcs |

144 |

|

Preform neck(inner dia.) |

mm |

26-30 |

|

Preform height(max.) |

mm |

120 |

|

Bottle diameter(max.) |

mm |

60 |

|

Bottle height(max) |

mm |

250 |

|

Heating ovens |

unit |

7 |

|

Infrared lamps |

pcs |

42 |

|

Max.heating power |

KW |

56 |

|

Specified power consumption |

KW |

50 |

|

Voltage |

V |

380V(50/60Hz) |

|

Low pressure air compressor |

|

Air capacity |

M3/min |

4.4 |

|

Pressure |

Mpa |

1.2 |

|

Motor power |

KW |

44 |

|

Tank |

M3 |

1.0 |

|

High pressure air compressor |

|

Air capacity |

M3/min |

5.0*30 |

|

Pressure |

Mpa |

3 |

|

Motor power |

KW |

25*2 |

|

High pressure freezing dryer equipment |

|

Air capacity |

M3/min |

5 |

|

Pressure |

Mpa |

3 |

|

Air inlet temperature |

℃ |

Less than 80 |

|

Power |

HP |

1.5 |

|

High pressure gasholder |

|

Volume |

M3 |

1 |

|

Pressure |

Mpa |

3 |

|

Cold water equipment |

|

Flow rate |

T/H |

2.9 |

|

Colling capcity |

Kcal/h |

24600 |

|

Outlet temperature |

℃ |

5-20 |

|

Power |

Kw |

5.3 |

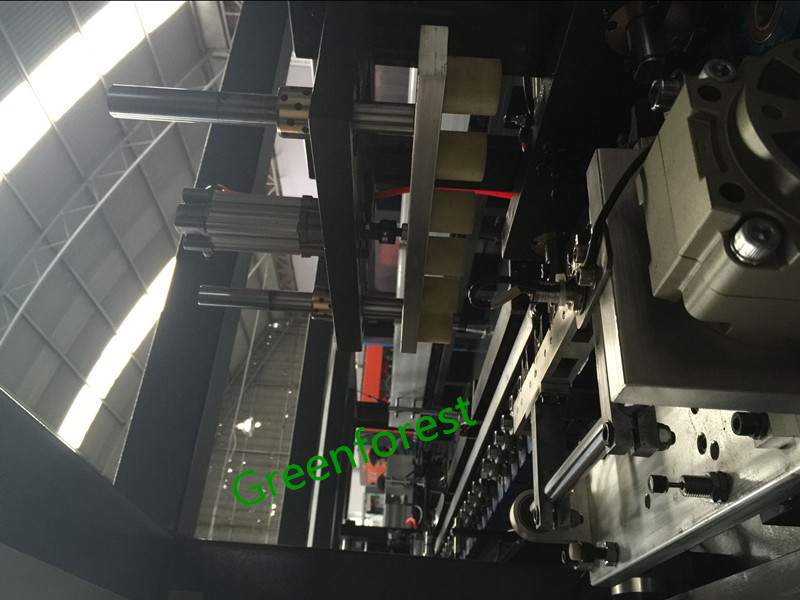

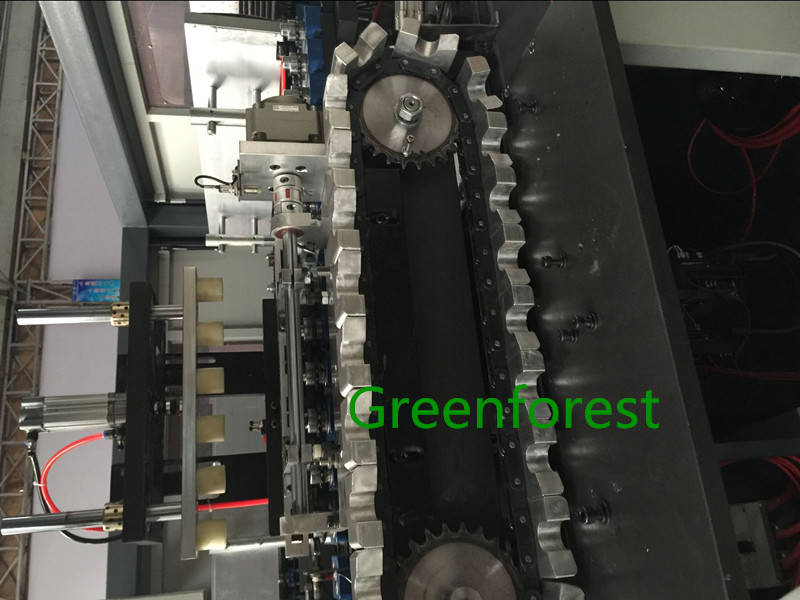

Automatic bottle blow moulder inner photos: